Bend, Don’t Break: Cut Costs and Protect Your Warehouse with Flexible Bollards & Barriers

Managing a warehouse involves countless moving parts. Forklifts weave through aisles, shelves are stacked high with stock, delicate machinery operates, and staff members all need to coexist safely. But what happens when damage occurs?

Some wear and tear, like minor scrapes and dents, are part of day-to-day operations. However, more severe damage can pose serious safety risks and lead to costly repairs or replacements. In worst-case scenarios, significant damage could even cause temporary closures, costing the company far more than repairs alone.

So, how can you limit this damage? One effective solution is using flexible bollards and barriers. While non-flexible options offer excellent protection, they can become costly when damaged and need replacing. This is where flexible designs shine.

Why Flexible Bollards and Barriers are a Game-Changer

In a busy warehouse, accidents are inevitable. Forklift drivers may misjudge a turn, shelves can get bumped, and walls or equipment may take a hit. While you can’t prevent every incident, you can limit the damage.

Flexible bollards and barriers are designed to absorb impacts, protecting your assets and reducing costs. Here’s why they work:

- Flexibility on Impact: Unlike rigid steel barriers, flexible bollards bend slightly when hit, reducing the risk of damage. Traditional bollards often remain bent or broken until replaced, increasing downtime and hazards. Flexible designs help protect forklifts and themselves by absorbing impact and self-righting after.

- Durability: Flexible bollards and barriers are built to last. The Flexbrite® bollard range, pictured to the right, is made from 100% polyurethane—designed to take a hit and fully flexible on impact. As the bollards bend, they absorb the force, bend, and then self-right when the forklift moves away again, with minimal need for maintenance, repairs, or replacement. This example worked perfectly in the An Post Dublin Parcel Hub, protecting crucial parcel conveyors from pallet trucks.

- Cost-Efficiency Over Time: Since flexible bollards and barriers absorb shocks without breaking or causing damage, they save you from costly repairs. Over time, fewer repairs on forklifts, walls, shelving, and other equipment means less spent on repairs.

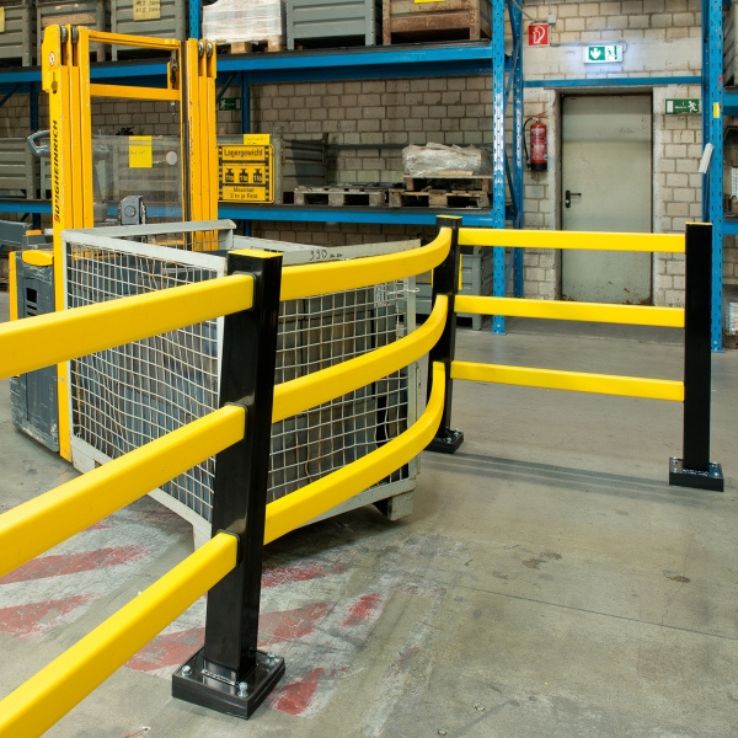

Flexible industrial railing systems, like the Black Bull Hybrid barriers, use a combination of steel posts and polypropylene rails to cover more considerable distances.

The rails will bend on impact from forklifts. If they become worn over time, only the rails need to be replaced, minimising the cost of replacing the posts. Barrier kits also help to cover large spaces quickly.

Where Flexible Barriers and Bollards Work Best

Flexible barriers and bollards are perfect for various warehouse scenarios. Once you've carried out your own risk assessment you'll see exactly where they'll work best.

- Forklifts and Walls: Forklifts are powerful machines, and accidental collisions can be expensive. Flexible barriers create a cushion between forklifts and hard surfaces, preventing costly damage to both the forklift and the warehouse.

- Shelves and Equipment: Installing flexible bollards near high-traffic areas or around key equipment helps reduce the impact of accidental bumps. This means less damage to shelves, racks, and machinery, leading to fewer costly repairs and less downtime.

- Guidance and Delineation: Bollards and hoop barriers are ideal for creating lanes for forklifts or separating pedestrian walkways from equipment areas. Flexible barriers ensure that if an accident does happen, the risk of injury or damage is minimised. Barriers are crucial to employee safety, helping to reduce the risk they face on a daily basis.

Warehouse repairs already cost business owners thousands per year, so any way to reduce these costs is always welcome.

Imagine reducing the number of forklift repairs because impacts are softened or avoiding damage to expensive shelving units that hold your stock.

Aside from reducing costly warehouse accidents, one of the biggest advantage of flexible warehouse barriers is the long-term savings. By reducing the number of forklift repairs, protecting shelves and equipment, and minimising the need for wall or structural repairs, flexible bollards and barriers help free up your budget and time

- Reduced Forklift Wear and Tear: Every impact with a rigid barrier transfers shock to the forklift. Flexible bollards absorb these shocks, preventing long-term wear and tear on your vehicles.

- Lower Building Maintenance Costs: Minor collisions with walls or columns can result in significant repair bills over time. Flexible barriers soften the blow, helping avoid costly damage to walls, paint, and structures.

- Protection for Stock and Equipment: Shelving units and machinery are critical to operations. Flexible barriers act as a buffer, providing excellent rack protection to exposed racking and storage