Wheel Chocks

A range of heavy-duty Wheel Chocks for car, truck, and aircraft parking. Long-lasting and secure asset protection for loading bays, construction sites, and airports.

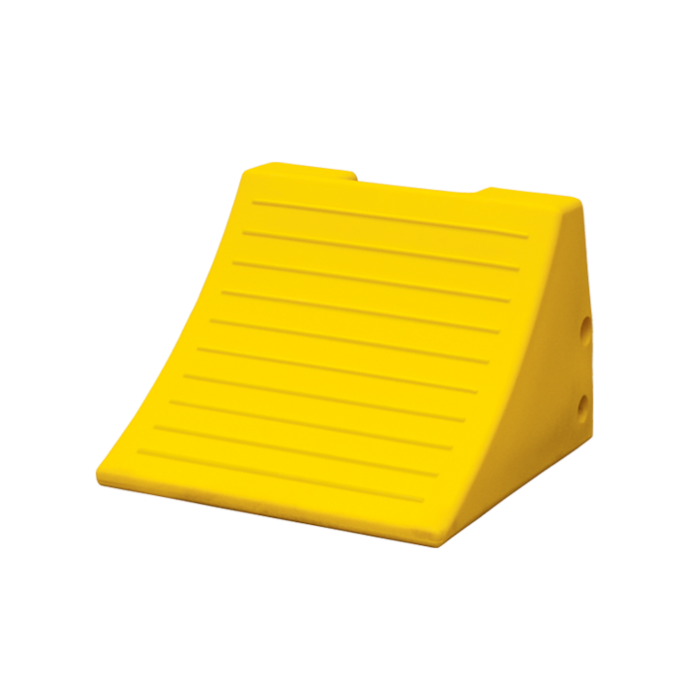

SKU: 751212

Pittman®

GHP Yellow Wheel Chock - 12

Sale price£30.00ex VAT

For Cars, Vans or Trailers - Max Load 5 Tonnes

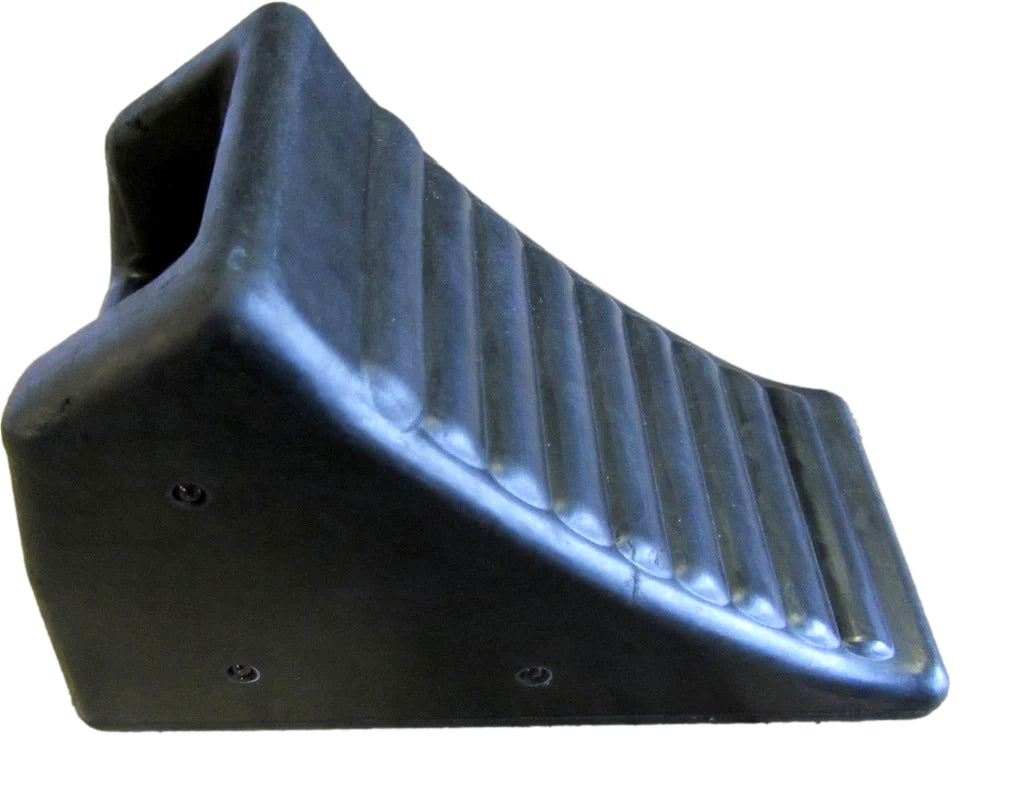

SKU: 751211

Pittman®

Handled GHP Wheel Chock

Sale price£26.00ex VAT

For LGVs and Vans - Max Load 10 Tonnes

SKU: 751217

Pittman®

GHP Aircraft Wheel Chock 2

Sale price£45.00ex VAT

For Light Aircraft - Total Weight 6.6kg

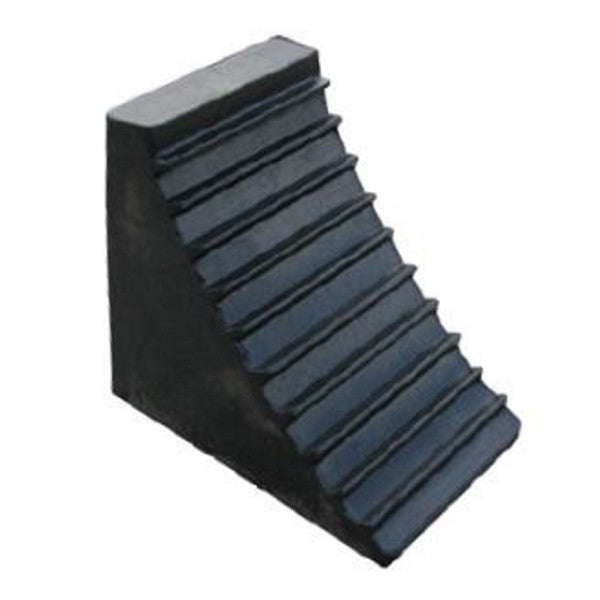

SKU: 751210

Pittman®

Small GHP Wheel Chock

Sale price£9.95ex VAT

For Cars and Trailers - Max Load 1 Tonne

SKU: 751218

Pittman®

GHP Aircraft Wheel Chock 8

Sale price£93.00ex VAT

For Commercial Aircraft - Total Weight 14kg

SKU: 862502

Pittman®

GHP Aircraft Wheel Chock 5

Sale price£86.50ex VAT

For Commercial Aircraft - Total Weight 13kg

SKU: 862501

Pittman®

GHP Aircraft Wheel Chock 4

Sale price£58.00ex VAT

For Commercial Aircraft - Total Weight 9kg

SKU: 862504

Pittman®

GHP Aircraft Wheel Chock 7

Sale price£69.00ex VAT

For Commercial Aircraft - Total Weight 11kg

SKU: 862505

Pittman®

GHP Aircraft Wheel Chock 9

Sale price£137.33ex VAT

For Large Commercial Aircraft - Total Weight 21kg

SKU: 729542

Pittman®

GHP Aircraft Wheel Chock Black/Yellow

Sale price£95.00ex VAT

For Commercial Aircraft - Total Weight 8kg

SKU: 729554

Pittman®

GHP Aircraft Wheel Chock - 333mm Long

Sale price£131.50ex VAT

For Commercial Aircraft - Total Weight 8kg

SKU: 729553

Pittman®

GHP Aircraft Wheel Chock - 500mm Long

Sale price£143.50ex VAT

For Commercial Aircraft - Total Weight 12kg

SKU: 749084

Pittman®

MC Heavy Duty Wheel Chock - 122 Tonne Capacity

Sale price£329.50ex VAT

For HGVs and Plant Machinery - Max Load 122 Tonne

SKU: 749085

Pittman®

MC Heavy Duty Wheel Chock - 275 Tonne Capacity

Sale price£419.50ex VAT

For Large HGVs and Plant Machinery - Max Load 275 tonnes

SKU: 749086

Pittman®

MC Heavy Duty Wheel Chock - 400 Tonne Capacity

Sale price£561.00ex VAT

For Dump Trucks, Loaders or Mining Vehicles - Max Load 400 Tonnes

SKU: 749087

Pittman®

MC Heavy Duty Wheel Chock - 427 Tonne Capacity

Sale price£459.50ex VAT

For Cranes, Loaders and Haul Trucks - Max Load 427 tonnes

SKU: 862746

Pittman®

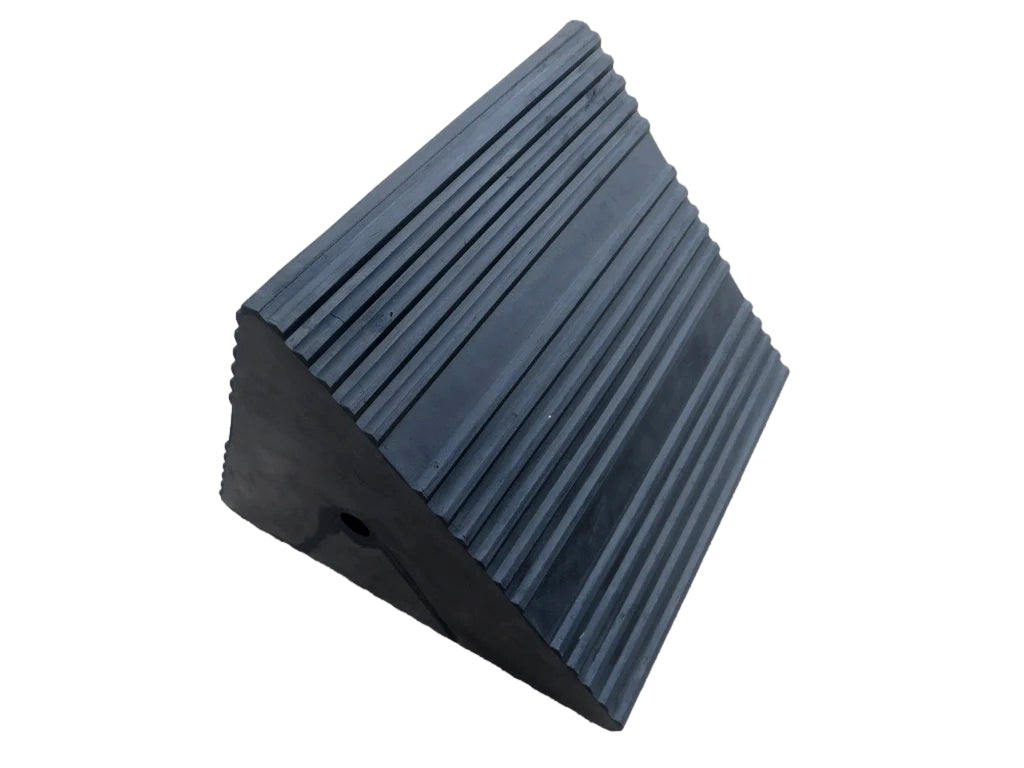

Heavy Duty Wheel Chock

Sale priceFrom £75.32ex VAT

For HGVs, Dumpers or Diggers - Max Load 44 tonnes

SKU: 862731

Pittman®

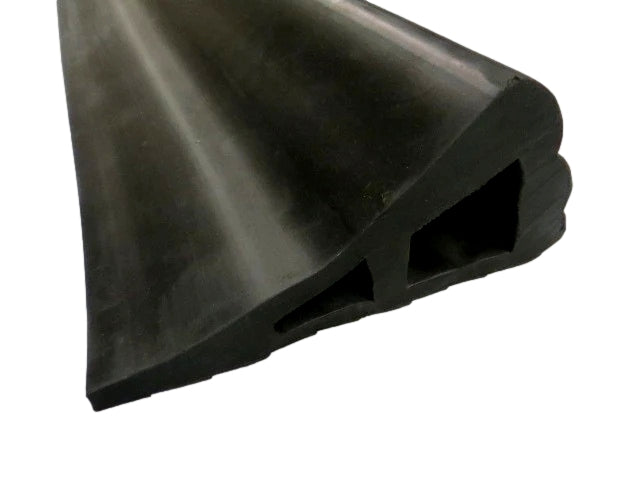

Lite Wheel Chock

Sale price£38.76ex VAT

For Lightweight Materials Chocking - Not Suitable for Vehicles