Rack Protection

Steel Rack Protection solutions designed to safeguard pallet racks from impact damage. Long-lasting, quick install, and made for warehouses and factories.

SKU: 763421

Black Bull

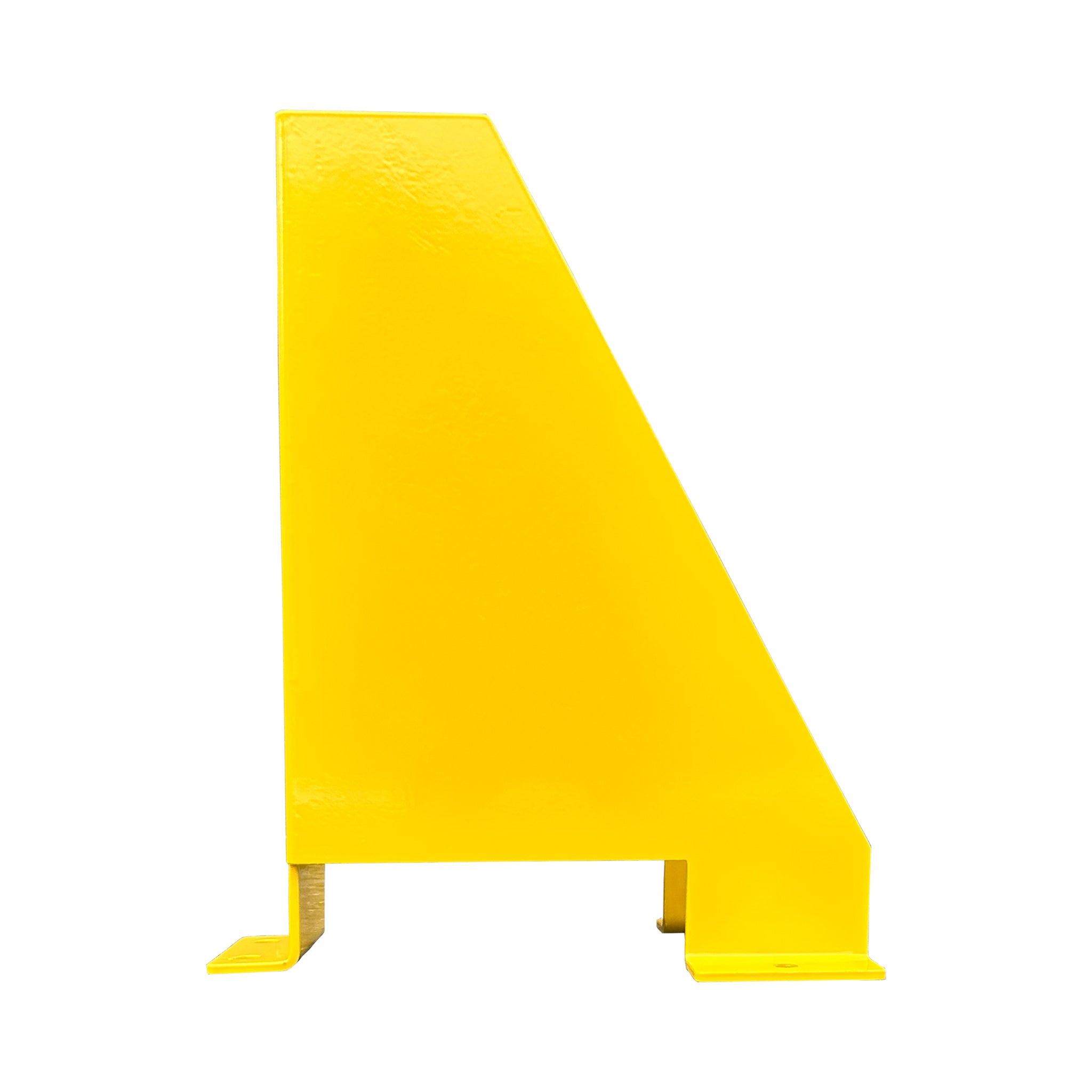

Black Bull Pallet Rack Protectors

Sale priceFrom £41.00ex VAT

Protection Against Forklifts and Machinery

SKU: 765217

Black Bull

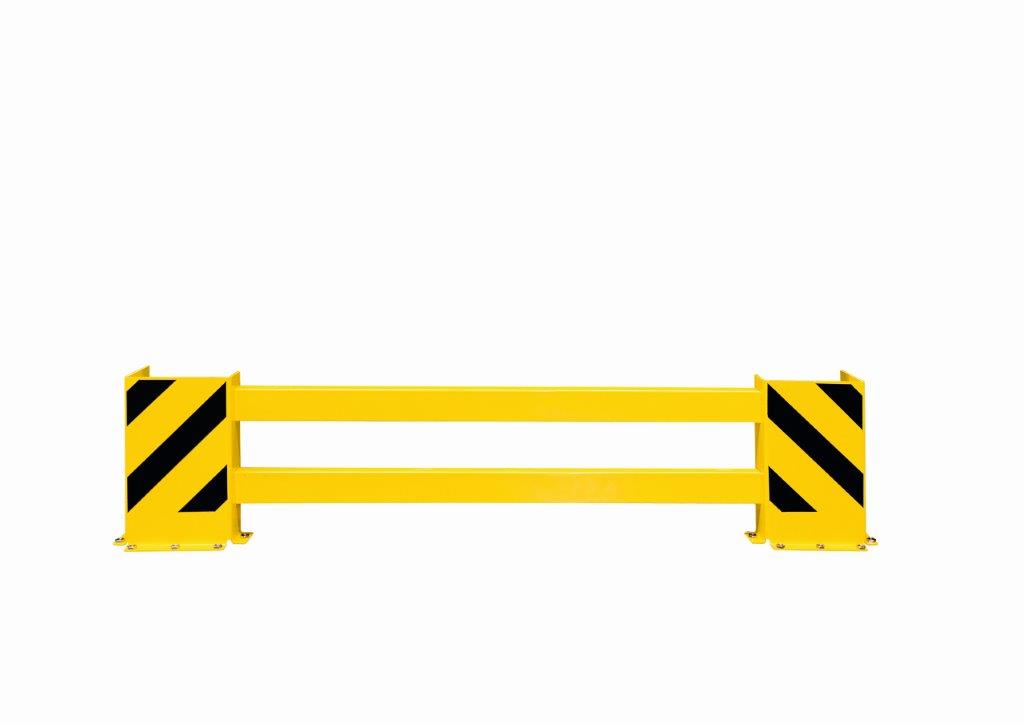

Black Bull Rack End Frame Protector

Sale priceFrom £463.00ex VAT

Full Protection for Pallet Racking End Frames

SKU: 765231

Black Bull

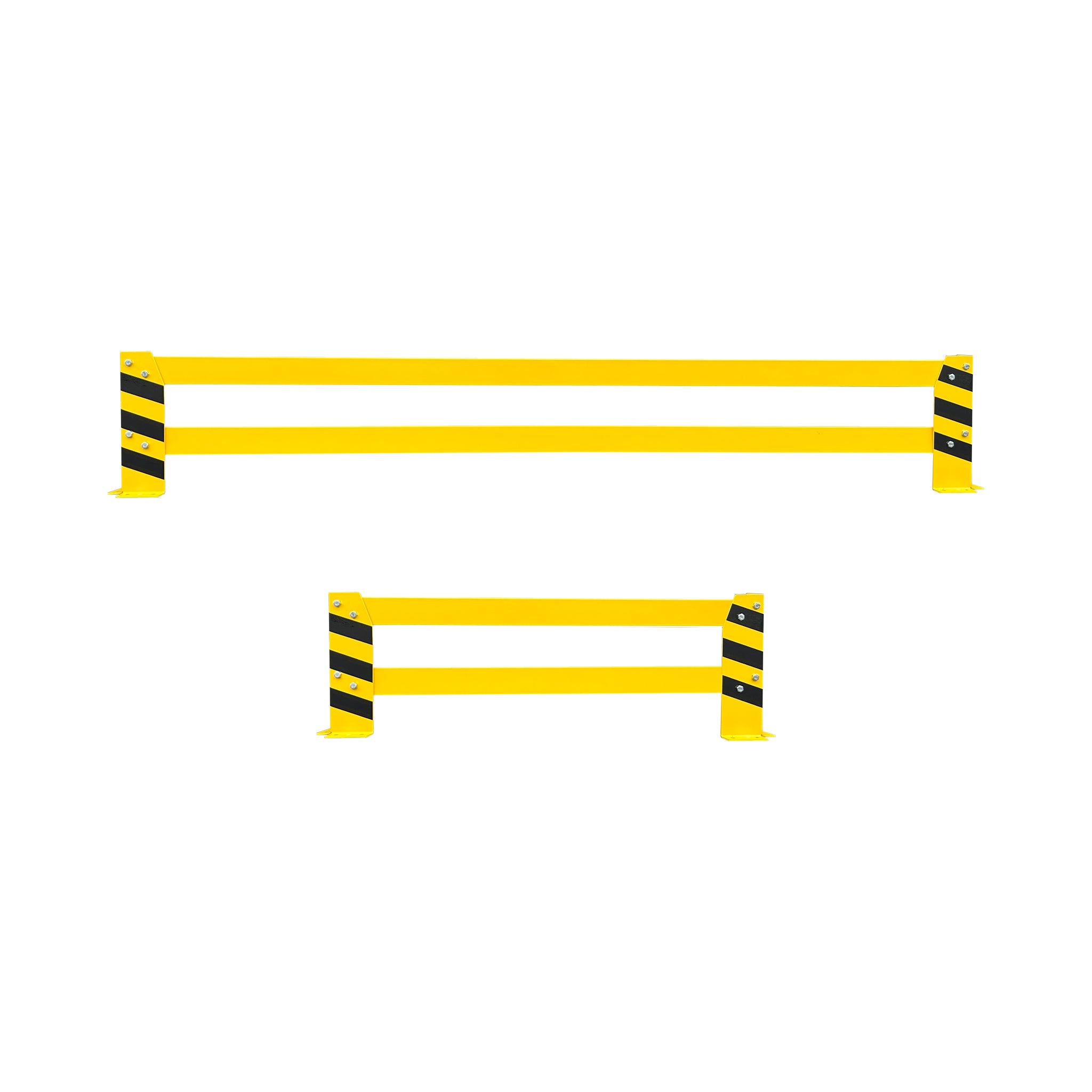

Black Bull Warehouse Collision Protection Bars

Sale priceFrom £32.00ex VAT

Ground-Level Protection Against Forklifts and Machinery

SKU: 765119

Black Bull

Black Bull Corner Protection Guard

Sale priceFrom £218.00ex VAT

90 Degree Design - Protects Assets and Machinery

SKU: 763438

Black Bull

Black Bull Steel Hoop Guards - Surface Mount

Sale priceFrom £173.00ex VAT

Perfect For Doorways, Stairs & Loading Docks

SKU: 763422

Black Bull

Black Bull Pallet Racking Protectors - Guide Rollers

Sale priceFrom £117.00ex VAT

Deflects Impacts - Ideal for Ground Level Pallet Storage

SKU: 765136

Black Bull

Black Bull Protection Guards XL

Sale priceFrom £366.00ex VAT

Extra Thick 108mm Diameter - Heavy Duty Protection

SKU: 765125

Black Bull

Black Bull Protection Guard

Sale priceFrom £120.00ex VAT

Heavy Duty Guards For Warehouse Assets

SKU: 765177

Black Bull

Black Bull Flex Protection Guard

Sale priceFrom £188.00ex VAT

Shock Absorbing Flex Pads - Bends on Impact

SKU: 765254

Moravia

Traffic-Line Column Protectors

Sale priceFrom £347.00ex VAT

Two-Piece Design for Easy Installation at Columns

SKU: 719046

Pittman®

Column Protector - Slimline

Sale priceFrom £233.55ex VAT

Protects Columns 100 - 160mm Wide

SKU: 719045

Pittman®

Column Protector - XL

Sale priceFrom £111.00ex VAT

Protects Columns 150 - 300mm Wide - Infills Available

SKU: 765277

Black Bull

Black Bull Steel Hoop Guards - Removable/Sub-Surface Mount

Sale priceFrom £176.00ex VAT

Optional Sub-Surface Fix or Socket Fix