Wheel Stops

A wide range of rubber and steel Wheel Stops for cars, vans and trucks. Durable and cost-effective asset protection for car parks, warehouses, and loading bays.

39% off

SKU: 756554

GNR

Park It 1800mm Rubber Wheel Stop (Blue)

Sale price£33.50

Regular price£54.50ex VAT

Limited Stock

SKU: 750212

XPT

XPT Wheel Stop 1800mm Yellow

Sale price£42.50ex VAT

The UK's Best Value Rubber Wheel Stoppers

SKU: 750213

XPT

XPT Wheel Stop 1800mm White

Sale price£42.50ex VAT

The UK's Best Value Rubber Wheel Stoppers

SKU: 756163

Moravia

Park Aid Rubber Wheel Stop 1800mm

Sale priceFrom £62.00ex VAT

The UK's Best Prices | Free Shipping

SKU: 895761

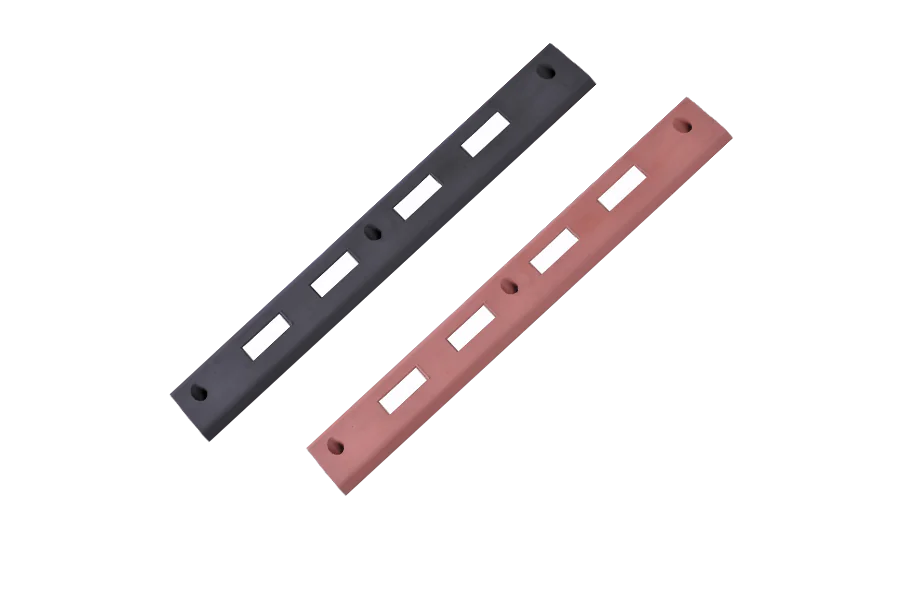

Pittman®

HGV Heavy Duty Wheel Stop

Sale price£87.90ex VAT

The UK's Best Prices with Fast Delivery

SKU: 756175

Moravia

Park Aid Rubber Wheel Stop 1200mm

Sale priceFrom £47.00ex VAT

The UK's Best Prices | Free Shipping

SKU: 756183

Moravia

Park Aid Rubber Wheel Stop 900mm

Sale priceFrom £35.00ex VAT

The UK's Best Prices | Free Shipping

SKU: 756186

Moravia

Park Aid Rubber Wheel Stop 550mm

Sale price£26.00ex VAT

The UK's Best Prices | Free Shipping

SKU: 756558

XPT

XPT Wheel Stop 1800mm Green

Sale price£79.50ex VAT

Protect EV Charging Stations from Vehicle Impacts

SKU: 899465

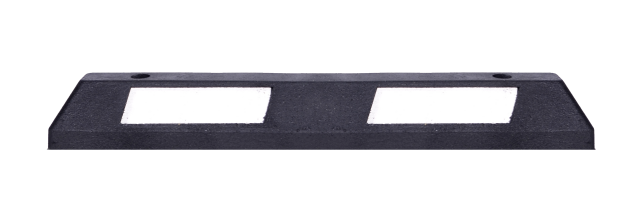

Pittman®

HGV Dock Wheel Stop

Sale price£220.00ex VAT

Help Bring Large Vehicles To A Halt

SKU: 756560

Pittman®

Economy Steel Tyre Stop - 600mm

Sale price£89.00ex VAT

Perfect For Use With LGVs

SKU: 756561

Pittman®

Economy Steel Tyre Stop - 2500mm

Sale price£430.00ex VAT

Strong, Resistant Guide For LGVs

SKU: 863720

Pittman®

Heavy Duty HGV Trailer Pad

Sale price£129.50ex VAT

Prevent HGVs Trailers From Sinking

SKU: 747250

XPT

XPT Rubber Curb

Sale price£9,999.00ex VAT

Extremely Flexible Kerbing for Road Projects

SKU: 899110

XPT

XPT Wheel Stop 900mm Yellow

Sale price£999.00ex VAT

Bring Cars to a Stop in Parking Bays

SKU: 899111

XPT

XPT Wheel Stop 900mm White

Sale price£999.00ex VAT

Reduce Vehicle Collisions in Car Parks

SKU: 756432

Moravia

Traffic Line Wheel Stop

Sale priceFrom £101.00ex VAT

Helps Define The End Of Parking Spaces