Loading Bay Wheel Guides

A range of all-steel Wheel Guides for safe and reliable truck parking in warehouses and loading bays. Aid truck parking and protect loading bay assets.

SKU: 862593

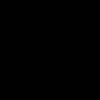

Pittman®

Straight Wheel Guides Pair

Sale price£767.61ex VAT

Rust and Corrosion Resistant

SKU: 862594

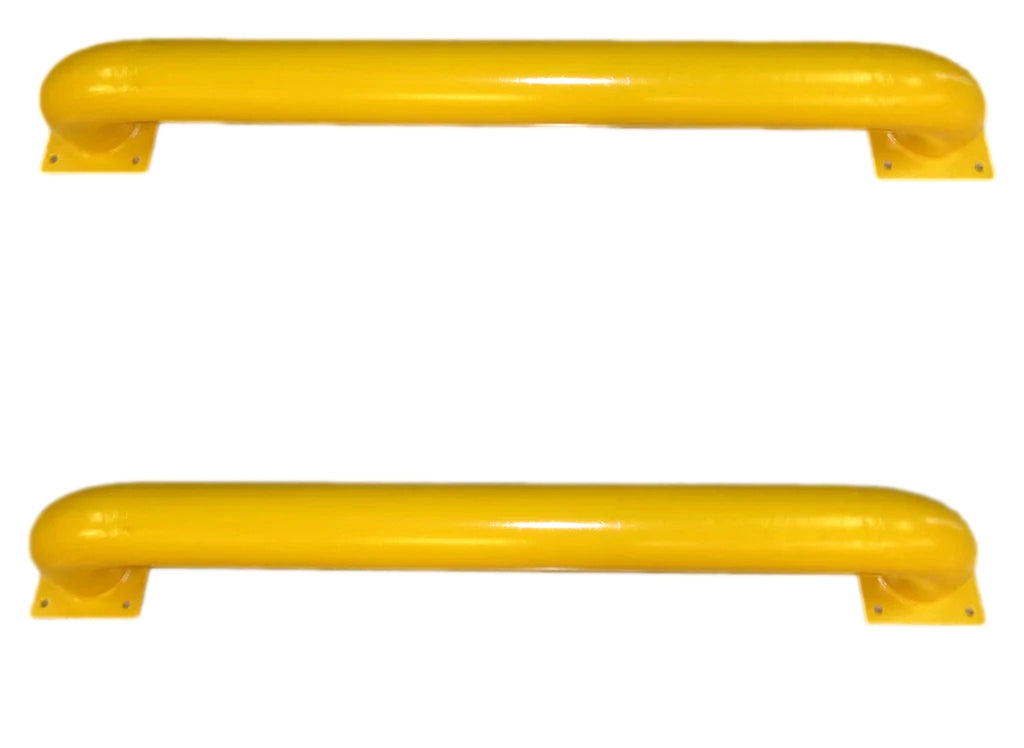

Pittman®

Cranked Wheel Guides Pair

Sale price£767.61ex VAT

Splayed Ends to Guide Truck Drivers

SKU: 763618

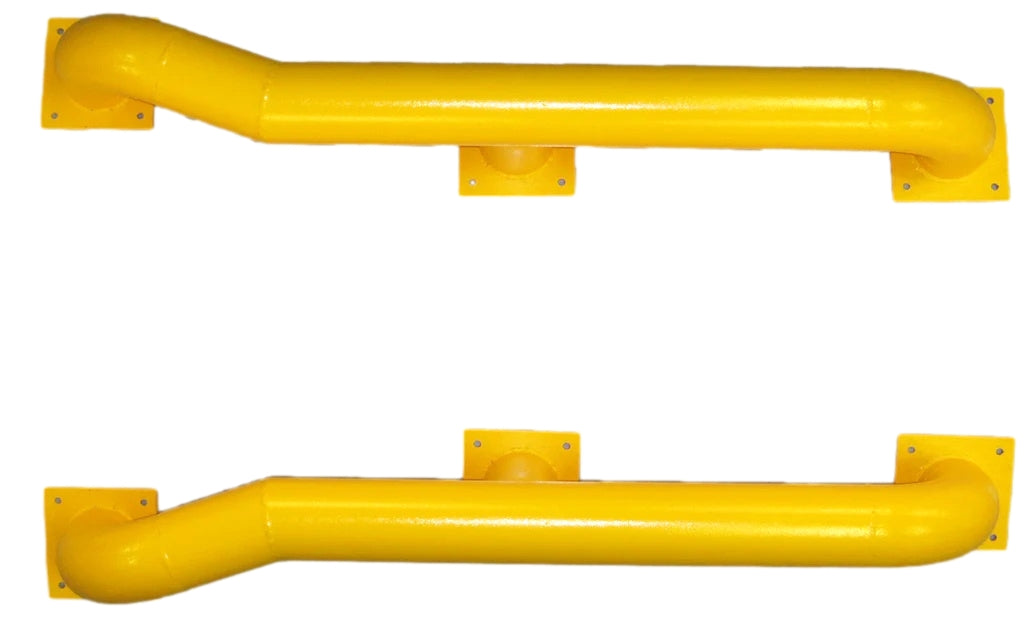

Pittman®

Low Profile Wheel Guides Pair

Sale price£767.50ex VAT

Suitable For Lower Profile Vehicles Or Trailers

SKU: 763621

Pittman®

Cranked Wheel Guide Pairs (3 Metre)

Sale price£831.00ex VAT

Galvanised Steel Impact Protection

SKU: 750714

Moravia

Black Bull Cranked Wheel Guide

Sale priceFrom £1,160.00ex VAT

Reduces Incidence Of Damage To Loading Bays | Free Shipping

SKU: 756560

Pittman®

Economy Steel Tyre Stop - 600mm

Sale price£89.00ex VAT

Perfect For Use With LGVs

SKU: 756561

Pittman®

Economy Steel Tyre Stop - 2500mm

Sale price£430.00ex VAT

Strong, Resistant Guide For LGVs

SKU: 895761

Pittman®

HGV Heavy Duty Wheel Stop

Sale price£87.90ex VAT

The UK's Best Prices with Fast Delivery