Warehouse safety is of the utmost importance where employees and assets are concerned. Having the right protection equipment in place is crucial to protecting workers while maintaining a seamless operational flow. A lack of proper protective equipment in a warehouse can lead to fatal injuries, especially where exposed employees and active work vehicles are concerned.

Alongside pallet racking protection, column protection and corner protection, hoop barriers provide one of the most reliable means for protecting employees and assets in the busiest of warehouse spaces and can greatly reduce the risk of costly warehouse accidents.

Warehouse accidents key statistics

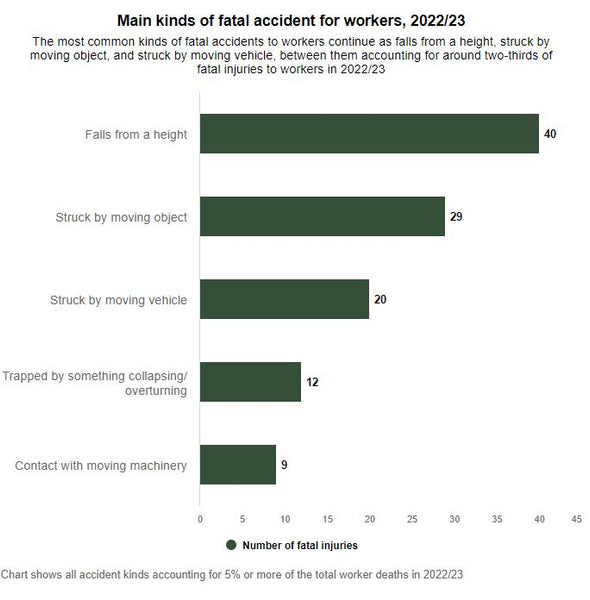

Unfortunately, warehouse accidents are still all too common in the UK. According to a HSE report for 2022/2023, there were 135 workers killed in the workplace over the space of the two years. Of these fatal accidents 40 were reported falls from a height, while there were 29 deaths from being struck by a moving object and 20 by a moving vehicle.

The figures are startling and highlight a greater need for protective systems in places like warehouses and factories, especially where there are work vehicles and working at height at play.

Source: https://www.hse.gov.uk/statistics/fatals.htm

Why Use Hoop Barriers?

Hoop barriers are designed to create a physical barrier that segregates pedestrians from high-traffic or machinery-operated areas, minimising the risk of workplace accidents. The hoop barriers themselves can play a critical role in reducing the risk of accidents by standing between pedestrians and work vehicles and acting as a "buffer" to reduce the risk of accidents.

Strategic Placement of Hoop Barriers for Maximum Safety

The key to best utilising hoop barriers is to determine their best placement throughout the warehouse. It is highly recommended to carry out full and thorough risk assessments of the area to ensure every possibility is covered.

Positioning the barriers around loading docks and warehouse racking can prevent accidental vehicle encroachment, a common source of warehouse incidents as highlighted in the HSE report earlier. This can create a clear barrier between work vehicles and pedestrians in loading bays, helping to reduce the risk of accidental impacts and boosting loading bay protection.

Installing barriers around valuable machinery or storage racks also protects assets and defines clear pathways for vehicles, reducing the likelihood of collisions. Protecting physical assets can greatly reduce the risk of repairs and replacements to key workplace machinery and infrastructure.

Enhancing Pedestrian Safety

One of the primary concerns in warehouse management is the safety of employees. Hoop barriers serve as a clear visual and physical guide, delineating safe walkways away from forklifts and other heavy machinery. This segregation is crucial in busy warehouses where pedestrian and work vehicle traffic is quite frequent.

Hoop barriers are typically installed alongside packing areas, assembly lines, or walkways to create a clear segregation between pedestrians and vehicles. They are also often used on high ledges, helping to reduce the risk of falls from height and to prevent stock or machinery from falling from platforms.

Flexible Solutions for Diverse Environments

Hoop barriers are generally quite versatile and come in various sizes and designs to suit specific warehouse needs. For larger runs, a combination of various barrier widths can be installed side by side to cover the bigger distances.

The hoops can also be installed at 90 degree angles end on end to cover corner spaces if needed. Installation is also usually done via integral base plates, so no long and costly excavations are required.

Some hoop barrier designs also come equipped with flexible feet or bases. This allows the barriers to bend and absorb impacts from work vehicles. This can greatly increase the life of barriers and reduce the need for replacement if a heavier accident occurs. This means that flexible barriers can reduce expensive warehouse repair costs. Consider using full industrial railing systems for larger spaces or combine hoops with warehouse bollards to maximise safety.

Durability and Low Maintenance

Most hoop barriers are typically made from galvanised steel. Hot-dip galvanised steel barriers especially increase barrier lifespan and provide long-lasting protection to warehouse spaces.

Their resistance to rust and corrosion means they can withstand the wear and tear of industrial environments with minimal maintenance required. This durability ensures that once installed, hoop barriers continue to provide safety benefits for years to come, representing cost-effective investment in warehouse safety.

The integration of hoop barriers into warehouse safety strategies offers a straightforward, cost-effective method to enhance the safety of both personnel and assets. Their robust design, combined with strategic placement, creates a safer work environment by clearly defining safe zones and protecting critical infrastructure from accidental damage.

Properly placed hoop barriers can help to reduce warehouse accidents overall, especially those involving falls from height and work vehicles.